Beixin Machinery has excellent processing and manufacturing capabilities. The first joint workshop is a steel structure workshop with a length of 180.5 meters and about 13,693 square meters; the second joint workshop is a mechanical mechanic and assembly workshop with a length of 180.5 meters and about 13,098 square meters; The third joint workshop is mainly used for surface treatment, with a length of 126 meters and about 3572 square meters; the company has 5 production workshops: structure workshop, heat treatment workshop, machining workshop, surface treatment workshop, assembly workshop; nearly 200 processing and production workshops Hoisting equipment. Beixin Machinery has obtained a number of invention patents and utility model patents in the process of R&D, design and manufacturing, which have been applied to actual production and manufacturing. Among them, the manufacturing capacity of plasterboard equipment can meet the production needs of users with an annual output of 60 million m2. Widely praised by users.

The main equipment includes 1 CNC flame plasma cutting machine, 2 CNC sawing machines, 1 CNC five-sided gantry milling, 2 vertical machining centers, 1 vertical four-axis machining center, 6 Doosan horizontal CNC turning centers, Doosan 2 horizontal CNC lathes, 1 ordinary planer milling machine, 1 planer planer, digital display 13 boring machine, ordinary vertical milling machine, horizontal universal milling machine, gear hobbing machine, gear shaping machine, slotting machine, vertical lathe, horizontal lathe, external More than 100 processing equipment such as circular grinders, surface grinders, centerless grinders, tool grinders, radial drilling machines, shears, bending machines, presses, etc., as well as box-type resistance furnaces, trolley-type box-type resistance furnaces, and well test Electric furnaces, salt bath electric furnaces, high-frequency quenching machine tools and other metal heat treatment equipment, as well as supporting hoisting equipment, overhead crane 16/3.2 tons 4 sets, 10 tons 2 sets, 5 tons 12 sets. It can produce dozens of sets of gypsum board production lines each year, with a mechanical processing capacity of 1,000 tons/year and a metal heat treatment capacity of 600 tons/year.

Video display of processing and manufacturing capabilities Equipment introduction

1. Cutting equipment

£¨1£©CNC plasma flame cutting machine

£¨2£©CNC semi-automatic feeding band saw

£¨3£©Ordinary band saw

£¨4£©Shearing machine

2. Forming equipment

(1) Rolling machine

(2) Bending machine

(3) Four-column press

3.CNC machining equipment

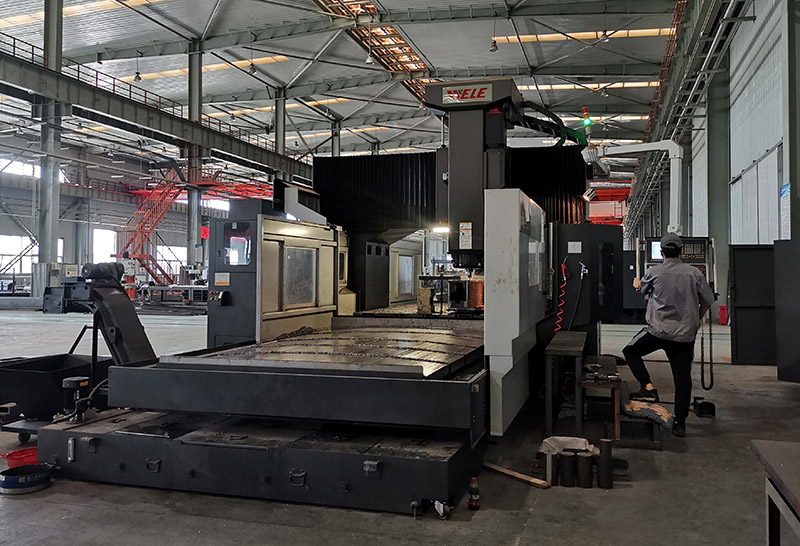

(1) Taiwan Weili ML-321 CNC five-sided gantry milling

Equipment function:

It can process general and high-precision workpieces such as large structures, boards, boxes, molds, and racks.

Features:

The machining accuracy is high, the efficiency is high, and the reliability is high. It has an automatic right-angle milling head and can process five sides in one clamping.

(2) VMC1300B vertical four-axis machining center

Equipment function:

It can process work pieces with complex contour shapes such as molds, shells, arcs, curved surfaces, and high dimensional accuracy requirements.

Features:

The machining accuracy is high, the efficiency is high, and the reliability is high. It can be programmed and processed simultaneously with four axes.

(4) Doosan PUMA 480 XLM horizontal CNC turning center

Equipment function:

It can process work pieces with complex contour shapes such as shafts, shells, arcs, curved surfaces and high dimensional accuracy requirements.

Features:

The machining accuracy is high, the efficiency is high, and the reliability is high. It adopts a 45-degree inclined bed with good rigidity.

4. Ordinary machining equipment

(1) CW61125B/8000 horizontal lathe

Equipment function:

It can process shafts, shells, and other heavy and super long shaft parts, and work pieces with high dimensional accuracy requirements.

Features:

The machining accuracy is high, the range is wide, the reliability is high, the rigidity is good, and the cutting force is large.

(2) Gantry milling (grinding) machine HDMMA-5GLJSS

Equipment function:

It can process work pieces such as large structures, plates, racks, and long grooves.

Features:

The processing efficiency is high, the reliability is high, it has a side milling head, which can be milled or planed and ground.

(3) Single-arm planer NHGO¢ò1500/600

Equipment function:

It can process work pieces such as large structures, plates, and long grooves.

Features:

High processing efficiency, high reliability and large cutting force.

(4) Vertical lathe

5. Heat treatment equipment

6. Finishing equipment

7. Environmental protection dust removal equipment

8. Surface treatment equipment

(1) Sandblasting room production line

The length, width and height of the largest work piece to be processed: 8m*3m*2.8m

(2) Spray booth production line

The length, width and height of the largest work piece to be processed: 8m*3m*2.8m

(3) Plastic spray production line

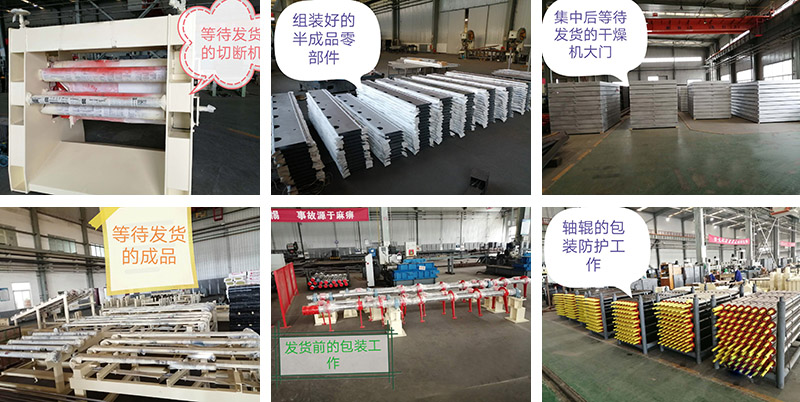

9. Pack and ship