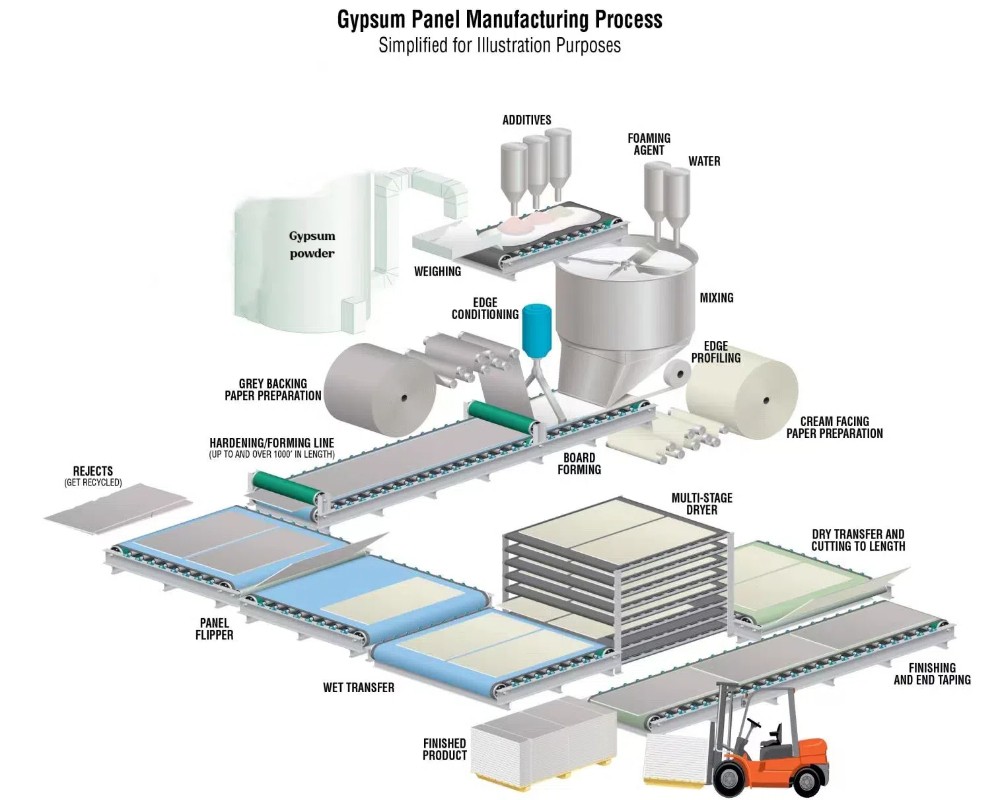

Process of making gypsum board

At present, gypsum board has been widely used in various buildings such as residences, office buildings, shopping malls, hotels, factories, etc. Under the international market situation, gypsum board is a new type of building material highly praised by governments around the world, with good development prospects and great international growth space. But how gypsum board is produced? Now we will share plaster board making machine simple process flow.

①Gypsum powder, water and other additives enter into mixer by automatic dosing system and conveying system.Gypsum slurry, generated from mixer after mixing,would be evenly scattered on the bottom paper.

②With continuous moving, and the process of extruding and forming, the slurry will be sealed by the top paper and bottom paper. Thus the wet plaster board is formed.

③While it conveyed by setting belt, the wet gypsum board gradually formed ,After board shaping, natural coagulation and automatic cutting. The wet plaster boards, arranged by programmed control system, Pass the cross conveyor and the plate turning machine and then quickly enter the dryer.

④Under strict controls in temperature zone of the dryer, the wet board dried by different temperature hot air blow. Then dry gypsum boards would be transported out of the dryer.

⑤Then plaster board be turned over again and folded together, cut into certain finished product size and edge sealed.

⑥Finally it comes to automatic stacker for stacking. Then can be transported to storage area by forklift after stacking