Learn about gypsum board production line

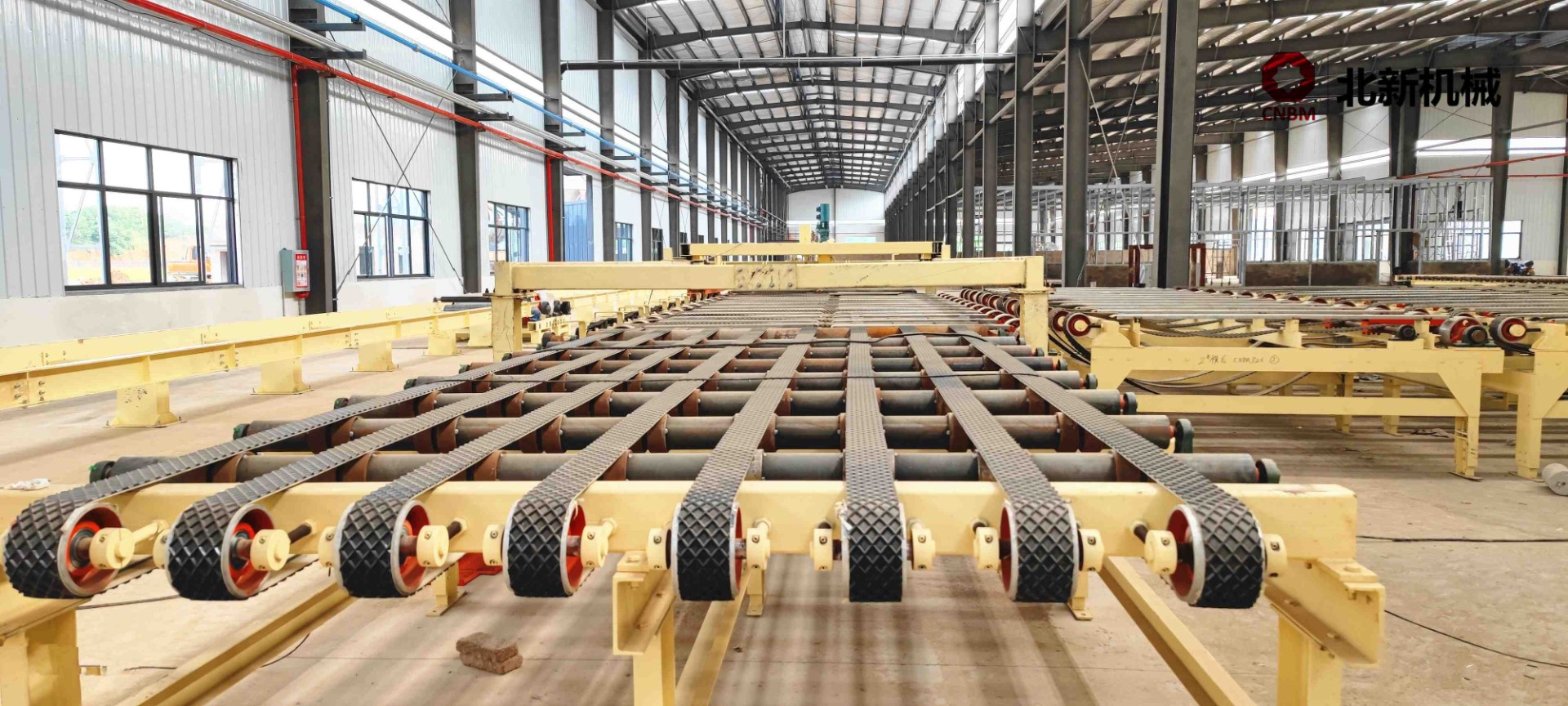

Gypsum board production line is a special equipment for producing gypsum board, which is composed of batching system, board making system, conveying system, horizontal system, drying system, board output system, Saw edge stacking system, etc. The equipment is characterized by small equipment investment , the product has high profit, can recover the cost in a short period of time, has no pollution, and the waste can be recycled and reused. Its production process is simple and easy to learn, and its raw materials come from a wide range of sources, so it is an ideal choice for investment projects.

Gypsum board is a material made of building gypsum as the main raw material. It is a building material with light weight, high strength, thin thickness, convenient processing, sound insulation, heat insulation and fire resistance. It is one of the new lightweight panels that are currently being developed. Gypsum boards have been widely used in interior partition walls, wall cladding panels (replacing plastering layers), ceilings, sound-absorbing panels and various Decorative panels, etc.

Gypsum board (divided into ordinary paper gypsum board (commonly used), fiber gypsum board, and gypsum decorative board) is made of gypsum as the main material, adding fibers, adhesives, and modifiers, kneading, pressing, and drying. It has the characteristics of fire prevention, sound insulation, heat insulation, light weight, high strength, and small shrinkage rate, and it has good stability, no aging, and insect-proof.